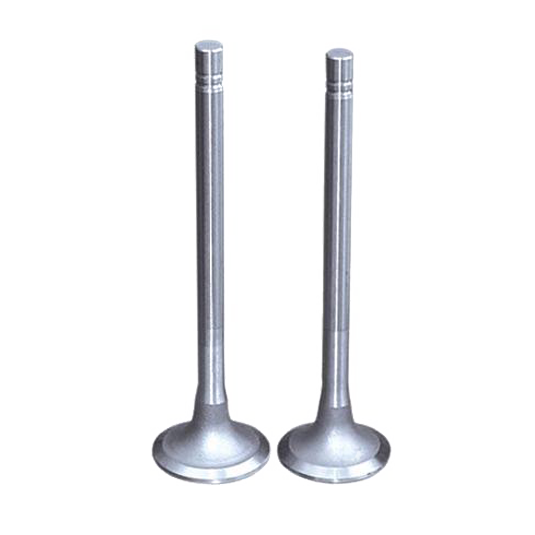

The valve is composed of a valve head and a stem. The temperature of the valve head is very high (intake valve is 570~670K, exhaust valve is 1050~1200K), and it also bears the pressure of gas, the force of the valve spring and the inertia force of the transmission component. Its lubrication and cooling conditions are poor, and the valve must be required It has certain strength, rigidity, heat resistance and wear resistance. The intake valve is generally made of alloy steel (chromium steel, nickel-chromium steel), and the exhaust valve is made of heat-resistant alloy (silicon-chromium steel). Sometimes in order to save heat-resistant alloys, heat-resistant alloys are used for the head of the exhaust valve, and chrome steel is used for the stem, and then the two are welded together.

The shape of the valve head includes flat top, spherical top and horn top. Flat top is generally used. The flat-top valve head has simple structure, convenient manufacturing, small heat absorption area, small mass, and both intake and exhaust valves can be used. The spherical top valve is suitable for exhaust valves. It has high strength, low exhaust resistance and good exhaust gas elimination effect, but its heating area is large, the mass and inertia are large, and the processing is complicated. The horn type has a certain streamline, which can reduce the intake resistance, but its head has a large heated area and is only suitable for the intake valve.